Aluminum alloy Doors and Windows products by which components?

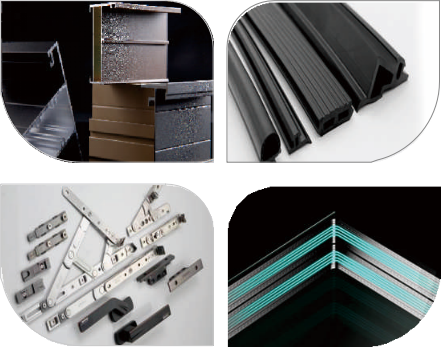

The common aluminum alloy doors and windows on the market are usually made of profiles, glass, hardware, and processing materials (connections)

Comprising of four parts: components, seals, etc., without considering special window types, glass, opening functions, etc In terms of processing technology, the highest cost proportion is for profiles, followed by glass and hardware components,

Commonly known as the “three major components” of doors and windows, consumers should pay close attention to them when purchasing door and window products.

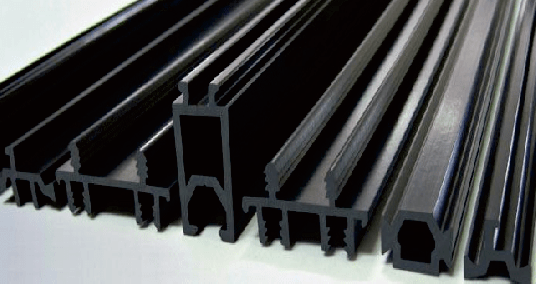

How to distinguish the quality of aluminum profiles for Doors and Windows?

When purchasing doors and windows, many merchants promote the use of concepts such as native aluminum, ecological aluminum, titanium alloy, aviation aluminum, etc. In fact, according to national standards, aluminum profiles for building doors and windows generally require the use of aluminum alloy profiles with alloy grade 6063, namely national standard aluminum profiles. But many unscrupulous manufacturers may use non-standard aluminum materials with added recycled aluminum or other impurities in order to reduce costs. Because it is difficult to distinguish the authenticity of national standard aluminum and non-standard aluminum only by the naked eye, in order to avoid being deceived, consumers can request door and window sales merchants to provide authoritative testing reports for door and window products or the profiles they use, which can quickly identify authenticity.

How to correctly understand the wall thickness of profiles?

- The stress strength of aluminum profiles for doors and windows is determined by various factors such as the material of the profile, structural design, the size of the profile against the wall, and the thickness of the profile wall. Simply considering the thickness of the profile wall is not comprehensive enough.

- Many unscrupulous manufacturers take shortcuts when producing products, only increasing the local wall thickness of the profiles to 1.8mm or even higher, and using this as a promotional point. Consumers should be wary of the concepts of “local wall thickness”, “average wall thickness”, and “overall wall thickness” when purchasing products. They must carefully observe whether the overall wall thickness of all main load-bearing profiles (frames, fans, and supports) is as advertised by the merchant.

- The higher the wall thickness of the profile, the better, because as the wall thickness increases, the cost of materials and product prices will also increase accordingly. Consumers should choose the most suitable door and window products based on their actual situation while ensuring safe use.

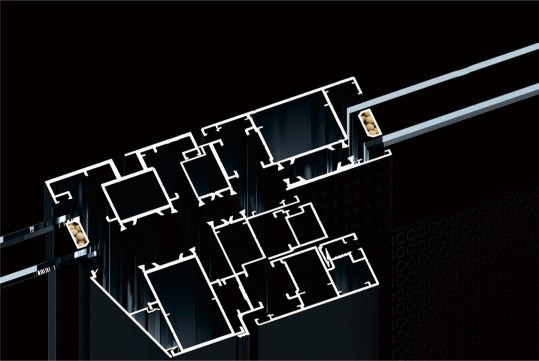

How to distinguish the good and bad of the heat insulation strip of the aluminum with broken bridge?

According to national standards, the material requirement for the insulation strip of broken bridge aluminum profiles is PA66GF25, commonly known as “nylon fiberglass” insulation strip. Consumers can pay attention to whether there is a component label of PA66GF25 on the profile insulation strip when choosing door and window products, and be alert to some unscrupulous merchants using inferior insulation strips of other materials. If necessary, merchants can provide corresponding testing reports. Poor heat insulation strips have poor aging resistance and strength, which will directly affect the strength of the overall window frame.

Is the heat insulation strip of aluminum broken bridge really wider the better?

Theoretically, the thermal insulation performance of aluminum profiles will improve with the increase of width. However, when the width increases to a certain extent, the improvement of thermal insulation performance of the profile will be limited. Instead, it may affect the stress strength of the profile due to the insulation strip being too wide. Therefore, if consumers do not have high requirements for door and window insulation performance, it is recommended that the width of the insulation strip be selected within the range of 14mm~30mm.

What is the wall size of door and window profiles?

The wall facing size of door and window profiles refers to the width of the contact surface between the profile frame and the wall. Many manufacturers’ door and window products are named after the wall facing size of the profile, such as the 110 casement window we usually hear, which usually refers to the wall facing size of the product being around 110mm. Under the same conditions, the larger the size of the wall, the better the load-bearing capacity of the profile in theory. However, the larger the size of the wall, the higher the material cost. Consumers should choose the most suitable product according to their own situation when purchasing products.

How to distinguish the quality of door and window glass?

When consumers understand door and window glass, the first thing they should pay attention to is the quality of the original glass sheet, as it directly affects the flatness, purity, and self explosion rate of the door and window glass. To ensure that the thickness of the glass sheet is consistent with the merchant’s promotion, it is recommended to choose glass sheets from domestic manufacturers such as China Southern Glass, Taiwan Glass, and Xinyi when purchasing doors and windows. At the same time, please pay attention to whether there is a “3C” mark on the glass of the doors and windows.

How to choose double-layer insulated glass, three-layer double insulated glass, and insulated laminated glass?

- If there are high requirements for insulation (such as in northern regions), it is recommended to choose three-layer double insulated glass;

- In most usage scenarios, choosing double-layer insulated glass is sufficient;

- If there are high requirements for sound insulation (such as houses facing the street), it is recommended to choose insulated laminated glass.

The pros and cons of choosing oversized glass?

With the improvement of living standards and aesthetics, more and more consumers prefer to choose oversized glass when designing door and window schemes. Indeed, the large glass without partitions in the middle makes the overall landscape more transparent and beautiful. But in order to ensure the safety performance of doors and windows, the use of oversized glass will inevitably greatly increase the thickness of the glass. For example, standard 5+20A+5 insulated glass. When the area of a single piece of glass reaches 5 square meters or more, according to national standards, the specification of the glass will be changed to 10+12a+10, which means that the thickness of the glass will be doubled. This will bring the following risks or drawbacks:

- The production cost of glass will increase significantly, and the selling price will also increase significantly.

- The transportation risk and cost of glass have increased, resulting in additional transportation, handling, or lifting expenses.

- The installation difficulty of glass has increased, resulting in additional installation costs.

- The significant increase in the weight of glass has raised higher requirements for the ground load-bearing capacity of installation space, increasing safety risks.

- The cost of use increases, and once damage or self explosion occurs in the later stage, the cost of glass replacement significantly increases.

Based on the above analysis, it is recommended that consumers be cautious when choosing large glass and fully weigh the pros and cons.

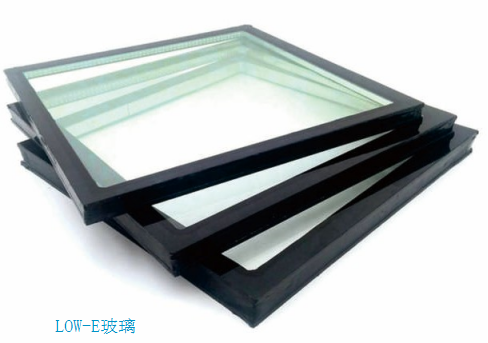

What is LOW-E glass and is LOW-E glass a better choice?

Low-E glass, also known as low emissivity glass, is a film product composed of multiple layers of metal or other compounds coated on the surface of glass. Compared with ordinary white glass, Low-E glass has better thermal insulation performance and is therefore widely used. However, it should be noted that under the same conditions, the transparency of glass coated with Low-E will decrease, and the price of Low-E glass is higher. Therefore, consumers should choose according to their actual situation (such as living balconies, bathrooms, kitchens, etc.).

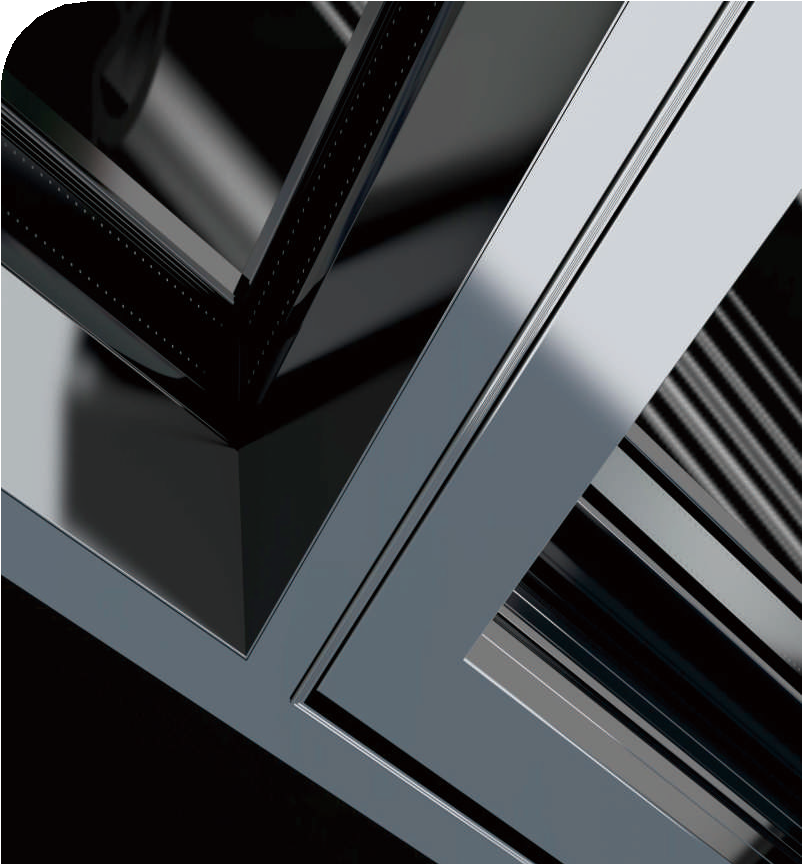

Why do we use an integrated bent hollow glass aluminum partition strip?

The use of integrated bending insulated glass aluminum spacers can further improve the sealing performance of insulated glass and reduce the risk of glass fogging. It is recommended that consumers choose insulated glass with this bending process as much as possible when purchasing.

How to distinguish the quality of door and window hardware?

The hardware system is the central system of doors and windows, and the opening function and load-bearing capacity of doors and windows are directly related to the hardware components. When consumers choose door and window hardware, they should focus on the durability and load-bearing capacity of the hardware, such as the normal opening times of the handle, the load-bearing capacity of the hinge of the flat window sash, and other indicators. It is recommended to choose hardware accessories from major brands and request merchants to provide brand authorization letters or product testing reports for these hardware products to avoid purchasing counterfeit and inferior hardware products.

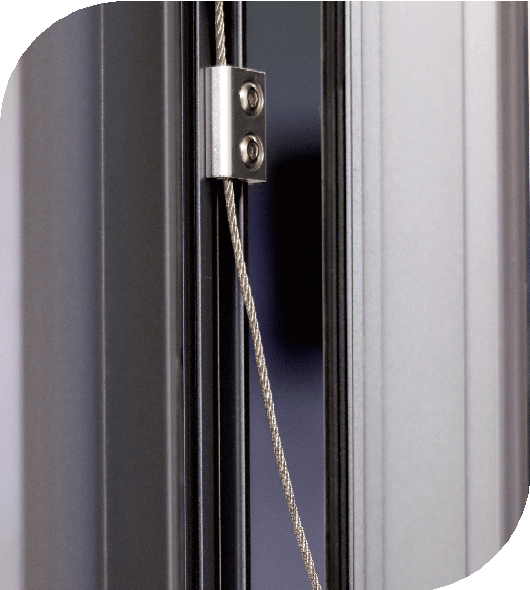

Is the safety rope useful?

Regular door and window brands usually have safety fall ropes installed above the opening sash of casement windows. Installing a safety fall rope is similar to adding a “double safety” to the window sash, so that it will not fall directly due to special circumstances (such as storms, severe impacts, etc.), thereby creating safety hazards. However, it should be noted that the safety anti fall rope can only provide a certain level of protection in a short period of time. In the event of a fan falling, measures must be taken as soon as possible to avoid greater safety risks.

How to distinguish the quality of door and window sealing strips?

Door and window sealing strip is an important material to improve the sealing performance of doors and windows. Most businesses in the market promote the use of EPDM sealing strip, but in fact, even EPDM sealing strip can be good or bad. Good sealing strip has smooth and soft surface, good resilience, and excellent anti-aging performance. Poor quality rubber strips generally become hard and crack after 1-2 years of use, reducing the sealing performance of doors and windows and increasing the risk of leakage.

What is the glue injection molding process?

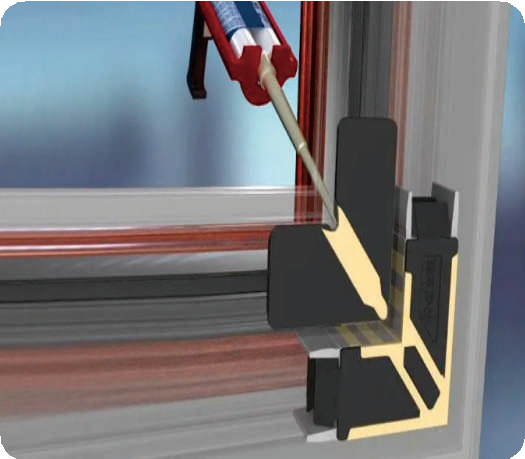

The splicing between profiles of door and window products usually requires built-in corner codes to improve the splicing strength. Taking the 45 ° angle splicing as an example, the glue injection process is to inject corner glue between the corner code and the profile gap, so that the glue fills the gap and cavity between the corner code and the profile. This can improve the splicing strength to a certain extent and prevent loosening and misalignment of the aluminum profile and corner code; More importantly, it greatly improves the sealing performance of the corner assembly and reduces the risk of water leakage at the corner assembly.

What is the splicing section adhesive process?

Aluminum profiles are metal materials with a hard texture, which cannot guarantee a completely tight fit when splicing profiles together. Therefore, for high-quality door and window manufacturers, a special adhesive, commonly known as “section adhesive,” needs to be applied to the contact surface of the two profiles before splicing. The sealing of the profile splicing area using section adhesive technology will be significantly improved, further reducing the risk of water leakage in doors and windows.

What are the main indicators that determine the performance of doors and windows?

According to national standards, the performance of doors and windows is usually determined by five indicators, namely “air tightness, water tightness, wind pressure resistance, thermal insulation, and sound insulation”, commonly known as the “five properties of doors and windows” in the industry. National standards have different rating standards for the five properties of doors and windows, and the higher the level, the better the performance. Consumers can request the merchant to provide a door and window inspection report when purchasing doors and windows. They can understand the performance of the door and window based on the data on the inspection report, and should not only listen to the merchant’s verbal promotion to avoid being deceived.

How to conduct acceptance inspection after the installation of doors and windows?

- Check the surface of the door and window profiles for obvious scratches, bumps, and whether the frame is horizontal and vertical.

- Whether the hardware components of doors and windows have been installed and debugged properly, whether the opening and closing are normal, and whether the operation is smooth.

- Check for obvious bubbles, impurities, scratches, and fogging on the glass of doors and windows.

- Whether the internal and external wall adhesives of doors and windows are complete and uniform, and whether there are any missing or uneven situations.

- Are there any obvious misalignment or gaps at the corners and joints of the profile assembly.

- Are all profiles, hardware, glass, and other configurations consistent with the merchant’s promotion or store samples.

- Whether the on-site protection measures are in place, and whether there is any damage to the walls and floors around the door and window openings.

- Has the completion site been cleaned properly, and have the waste and garbage generated during installation been cleared and taken away.

- Has the ‘Installation Completion Acceptance Form’ been submitted to the owner or their authorized representative for signature confirmation.

How to protect the legitimate rights and interests of consumers when purchasing doors and windows?

- Be wary of hidden charges and focus on the total price rather than the unit price. Door and window products are customized products, and there are many additional accessories and optional items due to different product solutions, which may indeed incur additional additional accessory or optional costs. Therefore, some merchants may use lower product unit prices as a gimmick to attract customers, but often end up charging high prices for doors and windows due to additional or optional items. So it is recommended that consumers focus on the total price of the door and window products when purchasing them, rather than the unit price.

- Be wary of false advertising. Due to the complexity of window design and product configuration, ordinary consumers may not have a professional understanding of the product. When promoting the product, merchants often deliberately exaggerate or even pass off inferior products as good. It is recommended to carefully observe before making a purchase and preferably ask merchants to provide corresponding testing reports. In addition, consumers are advised to carefully inspect the physical product upon receipt to ensure that the sample window products seen in the store are consistent with the products installed in their own homes, in order to avoid being deceived.

- Be wary of consumer traps. Consumers must sign a formal and legal order contract with the merchant when purchasing doors and windows, carefully check the agreed amount, product configuration, door and window scheme, delivery time, after-sales service and other terms in the contract, and require the merchant to provide a formal invoice to protect consumer rights.

- What suits oneself is the best. Don’t be superstitious about products and configurations. On the premise of ensuring the safety of door and window use and meeting functional requirements, what suits you is the best, saving money and worry.

- Big brands are more secure. If you really don’t have time to compare and understand, it is recommended to choose big brand door and window products as much as possible when purchasing, so that the quality is more guaranteed.